Why Yoda? Why not!

Why Yoda? Why not!

- One of the ways to look at the world is as a series of systems within systems within systems...you know, like those Russian Dolls.

- You can start at quarks and end up at the Universe, if you keep going up, or vice versa if you keep going down.

- Systems engineering, then, can refer to the development of projects, businesses, industries and even to national socioeconomic systems.

- But, many projects can make a business, many businesses can make an industry...perhaps there is something more to this

Systems Engineering appears to be all things to all people - or, put another way, it seems that many people, with many divergent viewpoints, lay claim to:-

- "using the systems approach"

or being - "the real systems engineers"

To bring some order to this seeming anarchy, yet without suggesting any restrictions on the creativity and energy that such divergence implies, I have proposed a 5-layer model of systems engineering, as follows:-

Contents

Socio-Economic, the stuff of regulation and government control

Industrial Systems Engineering, or engineering of complete supply chains/circles. Many industries make a socio-economic system. A global wealth creation philosophy. Japan seems to operate most effectively at this level

Business Systems Engineering - many businesses make an industry. At this level, systems engineering seeks to optimize performance somewhat independent of other businesses

Project or System Level. Many projects make a Business. Western engineer-managers operate at this level, principally making complex artifacts.

Product Level. Many products make a system. The tangible artifact level. Many engineers and their institutions consider this to be the only "real" systems engineering

![]()

The 5 layers form a "nesting" model, i.e. many products make a project, many projects make a business, many businesss make an industry and many industries make a socio-economic system.

Clearly, these statements are only approximate.

- A socio-economic system has more in it than just industries.

- A business has more in it than just projects, and so on.

Nonetheless, the 5-layer model provides a useful basis for illustrating how each level "lives within", and contributes to, the one above. For that reason, each layer will be presented in turn, starting at the bottom - Layer 1.

Level 1 - Product Systems Engineeering

Level 1 is the systems engineering of artefacts

- Words in blue indicate basic engineering approaches aimed at the creation of an artifact somewhat in isolation from other artifacts, together with which it might form part of a larger system.

- Words in black, in the figure above show the various factors and considerations necessary to ensure that the artifact is conceived, designed and created as part of a wider whole, into which it will fit like a hand in a glove

- Experienced engineers work in this fashion as a matter of course. Hence many are inclined to suggest that systems engineering is little more than common sense. and they're right, except that common sense can prove singularly uncommon...

![]()

Level 2 - Project Systems Engineering

Level 2 Systems Engineering is the System or Project Level

There are many patterns, or strategies, that can be, and are, followed at this level. The figure above shows a classic approach, going from top to bottom, with the generation of options and of criteria being conducted in parallel. Criteria for a good solution to the requirement are derived from:-

- that customer/user requirement,

- the environment into which the eventual product or service will be placed, including other systems with which it will interact

- the business objectives of the company concerned

- the capabilities of the company,

- the resources available to the company

Note that:-

- The eventual test and integration environment is developed from the requirement and in parallel with the primary product or service

- Systems engineering persists throughout the project phase, maintaining coherence and balance between the developing parts of the eventual product or service

There are several approaches other than the classic one shown above. Options include:-

- Waterfall, in which each phase of a project (e.g. requirements analysis, design, implementation, maintenance) is completed before proceeding with the next - assuming no rework...

- Spiral, or Helical, involving the use of prototypes to elicit better understanding of the requirement and to explore potential solutions

- Evolutionary, in which new systems are incremental "improvments" on previous tried-and-trusted systems

- Simultaneous or Concurrent, in which:-

- activities which might otherwise be sequential are overlapped to reduce time to completion

- designs anticipate the needs of development, production, assembly, etc.

- Sashami - like waterfall, but with some overlap between phases

- Regression - which allows each phase to linger throughout the project

- Chaos - breaks the rigid notion of phases and allows them to come and go as the project evolves.

- Once rework breaks out, most projects de facto tend towards chaos.

- Managers may become unduly concerned about this state, which may offer the best performance in complex situations

- Goal-oriented, in which the objective is to create the emergent features of a goal system by synthesis and without reduction

All of which is running "underneath" the following overview model of Level 2 Systems Engineering:-

![]()

Level 3 - Business Systems Engineering

Business Level Systems Engineering is represented in the figure as having two main strands:-

- The first strand runs left to right along the bottom, with suppliers providing parts which are assembled and then sold into a market at the right.

- The second strand runs from centre-right, anti-clockwise. It represents the business creating new products or variants which are eventually inserted into the flow of products passing through the first strand

- Red lines indicate co-operation with suppliers. Businesses vary considerable in the degree with which they co-operate. Some do not, while others encourage joint conception, design, development, etc., involving potential suppliers at every stage.

At this level, it becomes evident that any business must balance the two strands, and that any business is really part of some larger organization.

![]()

Level 4 - Industrial Systems Engineering

Supply Chain Systems Engineering is an example of Industry-level SE:-

- The figure shows a typical supply circle, i.e. a supply chain that closes the loop through recycling.

- Goods and services flow clockwise around the loop.

- Control and wealth flow anti-clockwise

- Goods in use become obsolescent due either to failure or to innovation

- Failure causes customer dissatisfaction so, although they will buy a new product, customers may well choose a different supplier

- Innovation causes customers to perceive their current product as outdated or outmoded, so encouraging them to buy a new product while the old one may still be working. If innovation is too fast, customers can feel cheated, so there are limits to product replacement speed.

- The figure shows typical metrics which can be formulated at this level

- The whole process of circulation might be co-ordinated, possibly be a Keiretsu.

- While this is possible, it may not be acceptable within some socio-economic systems (Level 5).

- Alternatively, the whole circle may develop behind a lead supplier who organizes his suppliers, who then organize their suppliers, and so on.

- Competing Supply circles provoke each others price reductions and continual innovation...

Looking at the supply chain of the previous figure in more detail reveals how the different categories of systems engineering nest into each other. The lead company, the one that delivers to the market, is shown being supplied by one of several second tier suppliers. Together with the other companies in the supply chain, they are subject to supply chain systems engineering, which seeks to maintain a steady flow of products into the market place, while at the same time minimizing Work in Progress, and other forms of overhead that increase the unit production cost (UPC).

Each of the companies in the chain/circle is also concerned with its own manufacturing processes, which have to be consistent with the overall supply chain ethic - hence manufacturing systems engineering. Also within each company, there will arise a need to design and develop replacement products, new products and existing product upgrades. So, we can see project systems engineering running vertically. since the products are made from supplied parts, project systems engineering runs in parallel in the supplier companies, too. Joint IPTs, Integrated Product Teams, form to coordinate the activities in the companies. Such teams may be ad hoc, and comprised of only 5 - 7 people needed to make commercially and technically viable decisions.

Within the projects, there will be subsystems, and therefore subsystems engineering will be evident as shown in the figure, working at artifact Level 1.

We can also see Market Systems Engineering, making up the set. Part of Market Systems Engineering is heijunka, production smoothing. This operates in part by adjusting marketing and advertising. If demand is falling off, then advertising is increased to restore the steady flow of particular goods. (The whole system may be manufacturing and selling many different products/goods in parallel, of course.) Similalrly, if demand is rising, advertising may be tailed off, again to maintain level production rates. It can be shown that steady production rates for a product passing through the supply system result in minimal work-in-progress (WIP); both raising, and lowering, the production rate result in increased WIP, which contributes to raising UPC. Steady is best, hence heijunka.Part of the skill, of course, is to recognize when a product has run its course, and to neatly fit a new or modified product into the manufacturing stream without a hiccup.

So, in this overall figure, we can see four of the five layers of systems engineering at work, each layer nesting in the one above.

Notes:

- The creation and continual adaptation of the volume supply chain to changing markets, fashions, and competition, indicate that here we have a different form of systems engineering. The system in question is global, it does not have an obvious lifecycle, and systems engineering is on-line, live and interactive. Like an animal, the system in question metabolizes, continually replacing parts with newer parts, continually adapting its size, throughput, etc., with the Prime Directive of long term survival, rather than short term profit per se.

- An excellent reference for such systems and for this different approach to systems engineering is the book: "The Machine that Changed the World," by Womack, Jones and Roos, published as a result of a 5-year, 5million dollar study by MIT into the future of the automobile

![]()

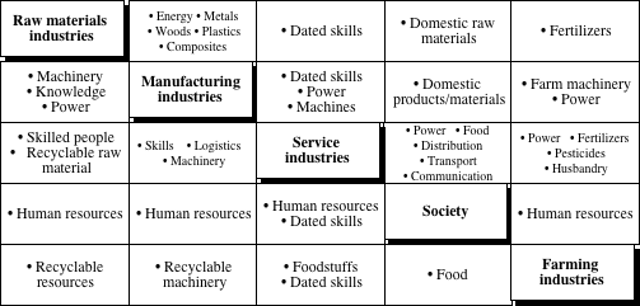

Level 5 - Socio-Economic Systems Engineering

Socio-Economic Systems Engineering is difficult-to-impossible to represent in a figure. Above, see my best shot to date. It takes the form of an N2 chart, so called because it has N rows and N columns, making N2 squares altogether.

- Participants in the system are entered in the shadowed boxes, while other boxes represent the interchange between participants.

- Output from any participant are in its row.

- Input to any participant are in its column.

- So, taking any square off the leading diagonal, it is simultaneously in the row and column that connects two particular entities.

Confused? Well, Raw Materials Industries give energy, metals, woods, plastics and composites to Manufacturing Industries - Row 1, Column 2. See?

Now, looking at the whole figure, you have a birds-eye view of the socio-economic system, with the major systems and their interchanges. The regulation, by politicians and economists, of the interchange patterns, can lead to Planned or Free-Market Economies:-

- Planned economy controls variety, interactions, matches outputs to inputs, including imports and exports. Economists predict the future, predictions fail, system weak through lack of variety, adaptability

- Free-market economy encourages variety, promotes chaotic input /output connections. Economists predict the future, predictions fail, system robust, adaptable through connected variety but its behaviour is uncertain

And, of course, changes occurring at this level filter all the way down through the levels to the bottom, affecting the way that industries, businesses and projects organize and behave. The same is true in the reverse, upwards, direction; changes in project performance impact on business, which has an effect on the Industry, and hence on the economy.

If you could imagine a globe representing the World, with one of these socio-econmic models on each and every nation and, further, if all the models were interconnected to show the flows ofmoney, goods and services between nations, then you would have the basis for a global socio-economic model. Now wouldn't that be something...

![]()